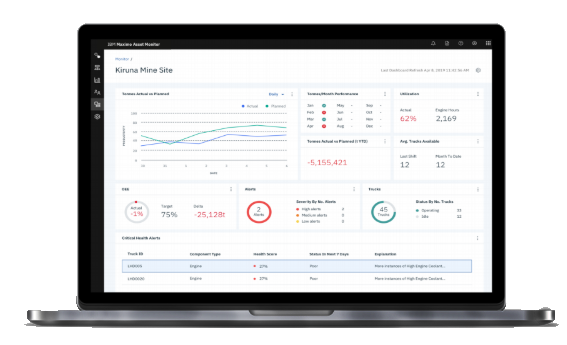

Maximo Asset Monitor

Monitoring solution that enables real-time visibility, root-cause troubleshooting, and AI driven alerts at scale

Key Benefits of IBM Maximo Asset Monitor

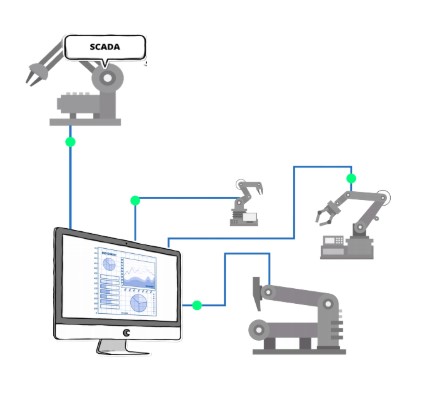

Connecting the Enterprise

Data integration from multiple sources of data about operating state.

Operate at Scale

Ability to scale and visualize operations across

enterprise through single dashboard.

AI-Powered Anomaly Detection

Advanced analytics and AI that can quickly detect

issues and leverage data from operating history.

Root Cause Analytics

Alert notifications and drilldown capabilities for

resolution teams.

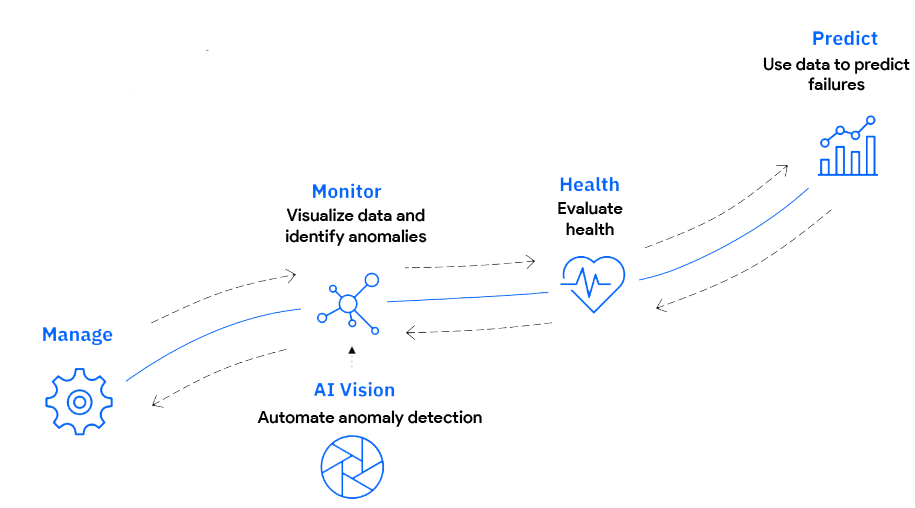

Journey to Predict

Monitor is the foundation for predictive maintenance

and asset health.

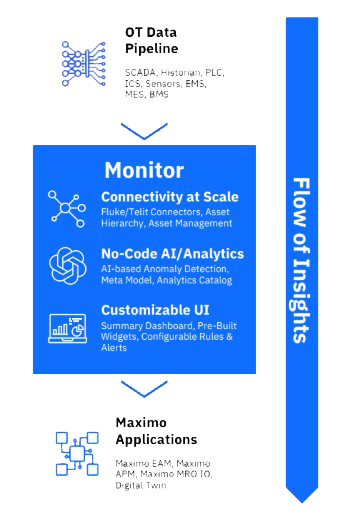

The solution

Connected enterprise

Connects OT data sources

Reduces operating costs through continuous

inspections

Improves asset and operational availability

Configurable dashboard for customized views

Scales easily across processes and sites

Improves operational control

Supports remote monitoring

Visibility at scale

AI-Powered Anomaly Detection

Leverages IBM’s market leading position in AI

Drives understanding beyond traditional

fixed-parameter alerts

Understand the patterns in the noise that are

easily missed

Enables drill-down for intelligent intervention

Access historical data for forensic analysis of

failure trends

Workflow integration to fast-path resolution

Root Cause Analytics

Journey to Predcit

Extract immediate value from your data

Gain access to IBM’s massive AI and

Analytics investments

Maximo Asset Monitor The Process

Connect

Prepare

Visualization

Investigate

Maximo Asset Monitor

The Process: Connect

Easily connect IT & OT enterprise data & devices at scale, while mapping to asset hierarchy

- Connect to IT and OT Data

Sources with Pre-built connectors

- Establish active connection

to EAM system

- Map entity data and devices

to Asset Hierarchy from

EAM system.

Maximo Asset Monitor

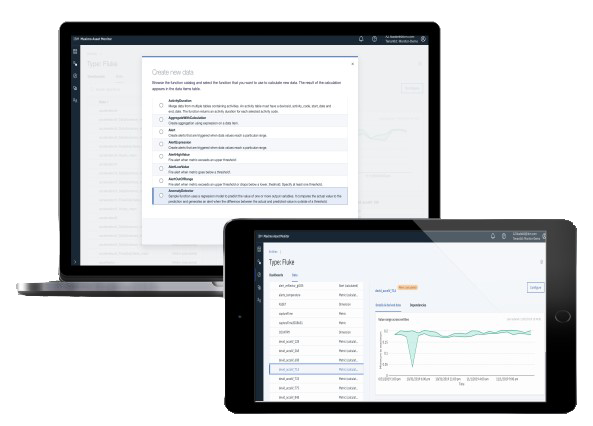

The Process: Prepare

Easily enable advanced analytics and AI-based anomaly detection for alerts in a low-code/no-code environment

One click add AI-based analytics from the prebuilt catalog of functions to apply to data

Set alerts based on analytics and anomaly detection scores

View result of all calculations in the data tab before using in summary dashboard

Maximo Asset Monitor

The Process: Visualize

Create customized dashboards with drag and drop pre-built widgets, showcasing embedded analytics, AI-

based alerts and visualizations of your operations

Build customized dashboards

based on use case with prebuilt

drag and drop widgets

Show outputs of AI-based anomaly detection and analytics, highlighting meaningful alerts within the widgets

Monitor your operations and KPIs, including key drivers for metrics like OEE, Availability, Uptime, and others

Maximo Asset Monitor

The Process: Investigate

View meaningful AI-based alerts, drill down from system to sensor, and create action to ensure uptime

Drill down from a plant to a system, component, asset, and sensor view

Investigate problems and root

causes that affect tracked KPIs

Create Automated Action ased on AI-based Alerts to ensure Uptime

Journey to Predictive

Improves uptime and reduces maintenance costs

Maximo Asset Monitor

Why Leverage?

- Enterprise level data aggregation & visibility

- Scale operations across processes & sites

- AI-powered detection of issues

- Enable drill down analysis for resolution teams

- Extensible IoT foundation